Quick and Efficient Rotary Equipment Solutions

J.F Menzia & Sons is a fabrication shop focused on offering comprehensive rotary equipment and welding services nationwide. Our experienced professionals have the knowledge and expertise to deliver high-quality services to companies. We can repair any aspect of rotary dryers, conditioners, and other rotating units.

Services Offered

Unsurpassed Project Management

We are dedicated to quality design, component supply, repair, installation, and maintenance of industrial processing equipment. With 100+ years experience in field service and maintenance, we have all the know-how to offer services that exceed your expectations. Our expert field service team goes above and beyond to deliver superior quality services to our valued clients.

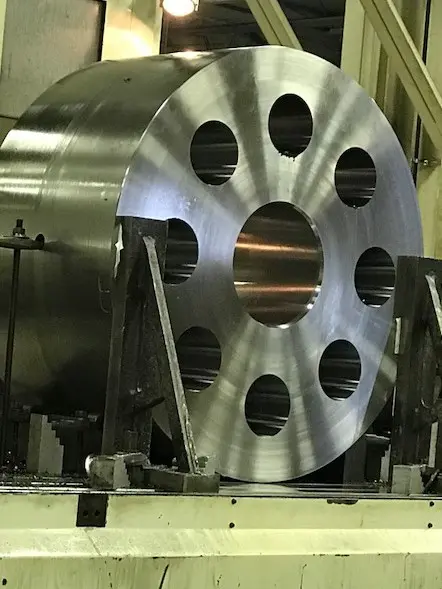

Complete Fabrication Shop

Rotary Equipment Design

We are very proud of our rotary equipment designs. We have included many time-tested features using modern day concepts to create rotary equipment that is reliable, low maintenance and competitively priced.

We have a 30,000 square foot facility with 120 ton overhead crane capacity. We are a one stop shop for feed hoods, shell, riding rings, flights, floating pad packages, trunnions, bases, pinions, pillow block bearings, thrust rolls, sprockets and discharge hoods. Our engineering design and fabrication capabilities allows for quick turnaround and delivery of any components.

Field Service Maintenance

Full service field expertise including on site Mig welding, submerged arc welding, crane operators, mechanics and millwrights. We also provide field services for inspections, alignments, resurfacing/grinding and more! Our personnel are field tested because this and we have an outstanding safety record with OSHA & MSHA.

We provide nationwide service and have built a reputation for excellence with leaders in the mining and agricultural industries. We would love to discuss how we can provide a beneficial service for you. Give us a call to schedule an on-site visit where we can evaluate your equipment needs.

Welding /Assembly Expertise

Certified welders fit up and final weld, to the specifications called out on internal drawings. We are National board and ASME certified (U & R) with a strictly adhered to quality program. We provide onsite and field ultra sonic testing. Materials of carbon steel, stainless steel, bronze, aluminum and hastelloy are but a few of the alloys we have experience in welding. Expertise in circumferential and straight seam submerged arc welding both in the shop and field capabilities. JF Menzia has a full service mechanical assembly department including pressing bearings as well as mounting trunnions, jack shafts and reducers to bases. Blasting and painting is provided